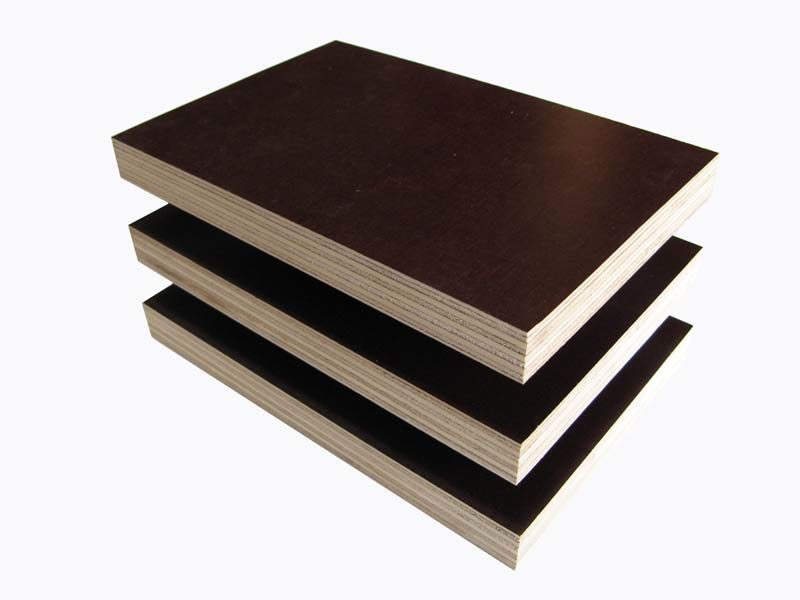

Ván phủ phim 15mm tại xưởng

Kích thước (dài × rộng): 1220mm x 2440mm

– Chiều dày: 15mm±1

– Gỗ ruột : Poplar

– Loại gỗ : AA

– Loại keo : Keo chống thấm nước WBP (Water Boiled Proof) Melamin và Phenol

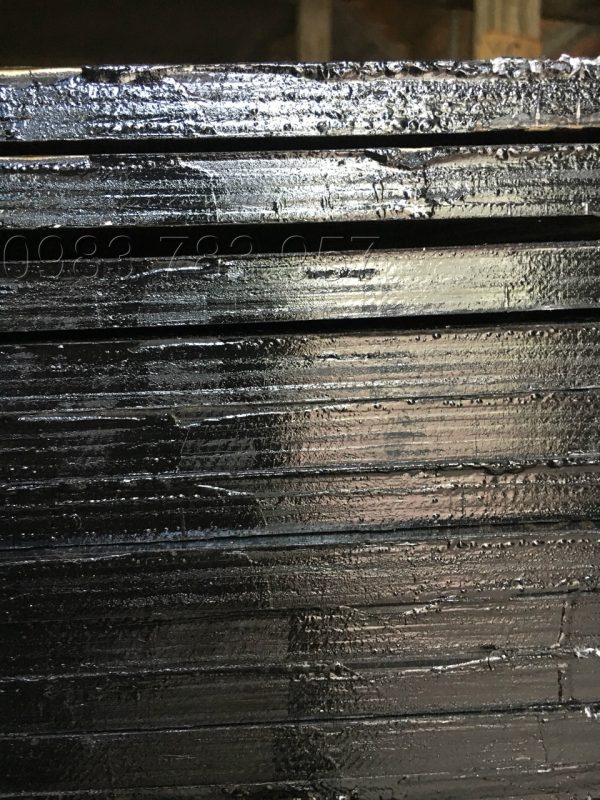

– Xử lý 4 cạnh : sơn keo chống thấm nước

– Loại phim : Nâu đen và đen nhập khẩu Singapore và Malaysia.

– Độ ẩm : < 12%

– Mô đun đàn hồi uốn theo :

+ Chiều dọc : 6100Mpa

+Chiều ngang: 5310Mpa

– Số lần tái sử dụng: ≥ 8 lần